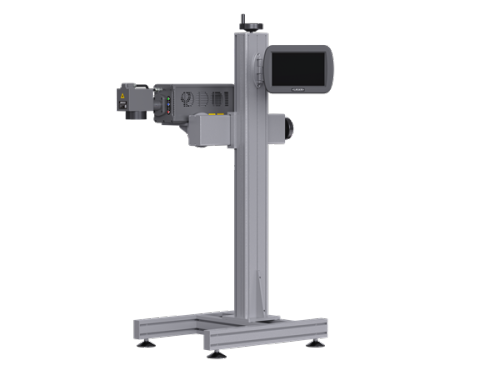

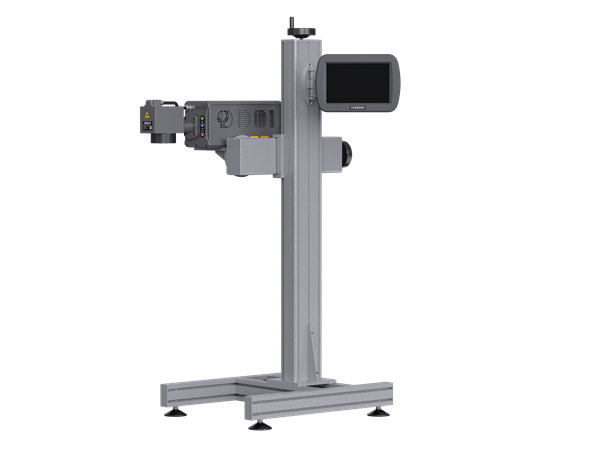

LINS-JET FSL20-C fibre laser printer

- Model

- LINS-JET FSL20-C

Review

Description

Title : With the technical support of 20 years inkjet printer working expensive, we have cooperated with experienced factories to develop CO2 laser printers with high quality and low price. Now we are looking for an exclusive agent.

Title

Advantages of ultra pulse CO2 laser in energy consumption:

1. In the input power of RF power supply, super pulse laser has the advantage of energy saving. Taking the 25-30w power range as an example, the input power of the traditional CW laser is between 400-500w. The input power of the SP30 super pulse laser of the corresponding access laser is only 250W, which saves 40%-50% of the energy. If the line laser works for 12 hours a day and the industrial power consumption is 1.5 yuan per kilowatt hour, each superpulse laser can save about 1500 yuan of electricity cost per year compared with the corresponding continuous laser.

2. In the energy consumption of material processing, the ultra pulse laser can greatly reduce the unnecessary energy consumption. Taking flight marking as an example, according to the characteristics of concentrated energy output in a short time, the effect of ultra pulse laser on materials is conical pits, so the effect of a series of ultra pulse lasers is a row of conical pits. However, due to the limitation of the laser output mode, the effect of continuous laser is equivalent to digging a groove on the material surface. Therefore, when the same marking effect is achieved, the volume of material to be processed is much larger than that of ultra pulse laser, and the laser energy is also required to be more accordingly. Therefore, the speed required for flight marking is not as high as that of ultra pulse laser.

We can prove this conclusion by simple mathematical derivation:

The general flying fight basically requires lattice. Taking this as an example, we assume that the spot diameter of the laser on the material, the distance between the two action points, and the depth of the pit / groove are. If a conical pit is required for each character to be printed by ultra pulse laser, the length (non closed character) or (closed character) required for each character to be printed by continuous laser shall be taken uniformly for the convenience of calculation.

Therefore, the volume of each conical pit hit by ultra pulse laser is:

The volume of material processed by typing one character is:.

For CW lasers, the volume of material processed by typing one character is:.

It can be concluded that the laser energy required by the super pulse laser is only 1/3 of that of the continuous laser when the same requirements can be met.

Now let's consider the marking speed.

The average speed of flight marking in general assembly lines is assumed to be packages per hour, which can be converted to packages per minute or per second.

If one character is required to be marked on each package, and the proportion of the area to be marked and the total length of the line is, the actual marking process speed shall be times the average speed. We can calculate the required super pulse frequency as:.

That is to say, the ultra pulse laser can meet the requirement of packaging every hour under the condition of frequency. The laser energy required for super pulse marking is only 1/3 of that of continuous laser, so the super pulse laser can completely meet the higher flying speed.

It can be seen that the energy consumption of the super pulse laser is much better than that of the continuous laser. For advocating low-carbon and low-energy life today, ultra pulse laser technology is undoubtedly of positive significance.

The ultra pulse CO2 laser also has a great price advantage. As mentioned above, equipment manufacturers and end users do not have to choose continuous lasers when they need the same marking effect. If the ultra pulse laser with corresponding power is selected, its price is not only 1/3 cheaper than that of the continuous laser. Considering the energy consumption factor of long-term use, the advantage of ultra pulse laser in the marking field is self-evident.

1. In the input power of RF power supply, super pulse laser has the advantage of energy saving. Taking the 25-30w power range as an example, the input power of the traditional CW laser is between 400-500w. The input power of the SP30 super pulse laser of the corresponding access laser is only 250W, which saves 40%-50% of the energy. If the line laser works for 12 hours a day and the industrial power consumption is 1.5 yuan per kilowatt hour, each superpulse laser can save about 1500 yuan of electricity cost per year compared with the corresponding continuous laser.

2. In the energy consumption of material processing, the ultra pulse laser can greatly reduce the unnecessary energy consumption. Taking flight marking as an example, according to the characteristics of concentrated energy output in a short time, the effect of ultra pulse laser on materials is conical pits, so the effect of a series of ultra pulse lasers is a row of conical pits. However, due to the limitation of the laser output mode, the effect of continuous laser is equivalent to digging a groove on the material surface. Therefore, when the same marking effect is achieved, the volume of material to be processed is much larger than that of ultra pulse laser, and the laser energy is also required to be more accordingly. Therefore, the speed required for flight marking is not as high as that of ultra pulse laser.

We can prove this conclusion by simple mathematical derivation:

The general flying fight basically requires lattice. Taking this as an example, we assume that the spot diameter of the laser on the material, the distance between the two action points, and the depth of the pit / groove are. If a conical pit is required for each character to be printed by ultra pulse laser, the length (non closed character) or (closed character) required for each character to be printed by continuous laser shall be taken uniformly for the convenience of calculation.

Therefore, the volume of each conical pit hit by ultra pulse laser is:

The volume of material processed by typing one character is:.

For CW lasers, the volume of material processed by typing one character is:.

It can be concluded that the laser energy required by the super pulse laser is only 1/3 of that of the continuous laser when the same requirements can be met.

Now let's consider the marking speed.

The average speed of flight marking in general assembly lines is assumed to be packages per hour, which can be converted to packages per minute or per second.

If one character is required to be marked on each package, and the proportion of the area to be marked and the total length of the line is, the actual marking process speed shall be times the average speed. We can calculate the required super pulse frequency as:.

That is to say, the ultra pulse laser can meet the requirement of packaging every hour under the condition of frequency. The laser energy required for super pulse marking is only 1/3 of that of continuous laser, so the super pulse laser can completely meet the higher flying speed.

It can be seen that the energy consumption of the super pulse laser is much better than that of the continuous laser. For advocating low-carbon and low-energy life today, ultra pulse laser technology is undoubtedly of positive significance.

The ultra pulse CO2 laser also has a great price advantage. As mentioned above, equipment manufacturers and end users do not have to choose continuous lasers when they need the same marking effect. If the ultra pulse laser with corresponding power is selected, its price is not only 1/3 cheaper than that of the continuous laser. Considering the energy consumption factor of long-term use, the advantage of ultra pulse laser in the marking field is self-evident.